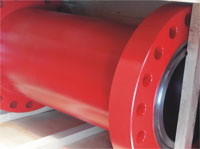

Dual

Plate Check Valve also is named as One Way Valve/Non Return Valve; it is used to prevent the

media flowing back in the pipeline. The Dual Plate Check Valve is automatic

valve, its closing and opening movements are driven by the energy of the media

in the pipeline, and do not need the external force.

1. TECHNICAL SPECIFICATION

PRESSURE 150LB~2500LB

SPECIFICATION 2”~48”

WORKING TEMPERATURE ≤570℃

APPLICABLE MEDIA WATER、STEAM、OIL、ACIDS、NATURAL GAS

2. SPECIFICATION STANDARD

DESIGN AND MANUFACTURE API594

END CONNECTION ASME B16.5

3. COMPOSITION AND MATERIAL

3.1). COMPOSITION

Dual

Plate Check Valve mainly compose of Body、Disc、Spring,

the Disc is used to open and close the valve.The Dual Plate Check Valves have

two Disc, Wafer between RF or RTJ Flanges.

3.2). MAIN MATERIAL

The body cavity Body and Disc connect and form contain the valve trim and the flowing medium, the body and trim materials are the key determining the medium and situation.

The Disc and Sealing Ring are the

important part of Check Valve, not only it bear the corrosion of the medium,

but also determining the Sealing Tightness and Working Life of the Check Valve,

so the material is very important, Dual Plate Wafer Check Valve also called

Butterfly Check Valve, Dual Plates design with spring to confirm closed seal.

4. CHARACTERISTIC

4.1).

The Fluid Resistance Of the Dual Plate Check Valve Is More Smaller

The fluid channel in the valve is straigh through, the cavity on the above of the valve is bigger, the disc would not keep out the channel inside the valve when openning and closing, the fluid resistance is very small.

4.2). The flowing direction of the medium in the valve channel is limited.

4.3). Under Low Pressure, the Sealing Property would not be influenced under the effets by the Spring.

5. INSTALLATION

5.1). Before out from the factory,

the Dual Check Valve have been approved by some inspection and performance test

as per the API598 and related standard, and clear away the greasy and sundries

inside and outside the valve, the entrance and exit of the channel of the Check

Valve also are plugged by the end socket..

5.4).When installing the Dual Plate Check Valve, it should pay more attention to the direction of the medium flow, the body has marked the arrow that shows the direction which medium flows.When installing, the direction that the medium would flows must stay the same with the arrow pointing, otherwise, the medium would be cut off by the disc.

5.5). When the Dual Plate Check

Valve are fixed on the pipelines, the body should not bear too much pulling and

pressure, bending and torsional stress.

6. OPERATION AND MAINTENANCE

6.1). OPERATION

The Dual Plate Check Valve is

automatic valve, it do not need the external force to work, it could work just

with the energy of the medium in the pipelines. When the medium in the pipelines

flow in the forwarding direction, the disc would then open, the medium would

get through. Otherwise, the medium flows in the reverse direction, the disc

would close to keep the medium backflowing.

6.2). MAINTENANCE

6-2.1 The Dual Plate Check Valve should be kept in dry and ventilated room, it is forbidden to be kept in open-air. The two ends should be plugged by the end socket in case the sundries would enter.

6-2.2 The Dual Plate Check kept for long term should have a peroidic inpection, clear away the sundries in the cavity, and coat the greasy on the processing surface.

6-2.3 The Dual Plate Check Valve that are working all the time on the pipelines should have periodic inspection to see if there are any wrong. If there is litte accidents, it should be solved in time, if the accidents are big, the Dual Plate Check Valve should be taken down and get repaired. The Dual Plate Check Valve that just get repaired and assemblied should get sealing test again. The accidents clearing and examine details should be recorded at length.

6-2.4 The Dual Plate Check Valve is

not allowed to be welded and repaired、removed at will、replaced

the valve part when working under pressure.

7. ACCIDENTS AND SOLUTIONS

|

ACCIDENTS |

REASON |

SOLUTIONS |

|

Inner Leakage(The leakage in the both sealing side between body and disck, seat) |

1.There are dirt at the sealing surface 2.The sealing is damaged by the shock of water |

1. Clear away the dirt at the disc and sealing surface, and cleap up by the kerosene. |

|

External Leakage (The leakge at the jointing between body and bonnet) |

1. The jointing bolts are asymmetrical at force. 2. The gasket is installed inclined or broken or become invalid after use. for long time. |

1. Screw up the jointing bolts and nuts in the body and bonnet. 2. Replace the gasket and install the gasket correctly. |